With the continuous advancement of Industry 4.0 and intelligent manufacturing, the implementation of an intelligent all-wireless production network has become an important direction for the development of modern manufacturing. The introduction of wireless networks not only enhances production efficiency and flexibility but also brings many other advantages, thereby promoting the overall competitiveness of the factory.

Customer Background

A factory in Suzhou requires a new type of automated and unmanned production line due to the inability of the original wired network architecture to meet the needs of flexible production. However, the cost of adjusting the production line is too high, necessitating the construction of a new network that meets the business needs of flexible production and simplifies manual operation and maintenance. It should be capable of automatically identifying network faults and performing self-repair to support the normal operation of the business.

Importance of Network Upgrade

- Enhancing Production Efficiency and Flexibility: Traditional wired networks are complex and costly to deploy. Wireless networks offer better flexibility, allowing equipment to move and reconfigure more freely, reducing downtime due to re-cabling, and thus increasing production efficiency.

- Real-Time Data Transmission and Processing: Wireless networks can quickly and stably transmit production data, enabling unmanned production lines to operate stably and orderly, automatically recording production progress and parameters, and promptly identifying and resolving issues to improve production efficiency.

- Reducing Maintenance Costs: Wireless networks simplify the extensive cabling of traditional networks, reducing maintenance complexity and overall costs. In the event of a fault, wireless networks can be remotely monitored for rapid diagnosis and troubleshooting.

Challenges Faced

- Network Coverage and Signal Strength Issues: Automated production lines require extremely high network speeds to avoid operational issues. To minimize problems, site planning and design must be thoroughly conducted beforehand, and advanced technologies must be employed to ensure network stability and speed.

- Network Security and Data Privacy Issues: Wireless networks are susceptible to hacking and data theft threats. Factories must place a high emphasis on network security and data privacy protection when implementing an all-wireless production network to prevent data leaks and system intrusions. This requires the implementation of encryption technologies and the establishment of multi-layer security mechanisms to prevent security incidents.

- Network Bandwidth and Latency Issues: In the intelligent production process of the factory, there are high demands for real-time data transmission and bandwidth. Engineers need to continuously optimize the network architecture and implement traffic management to ensure that the network bandwidth meets the requirements.

Solution

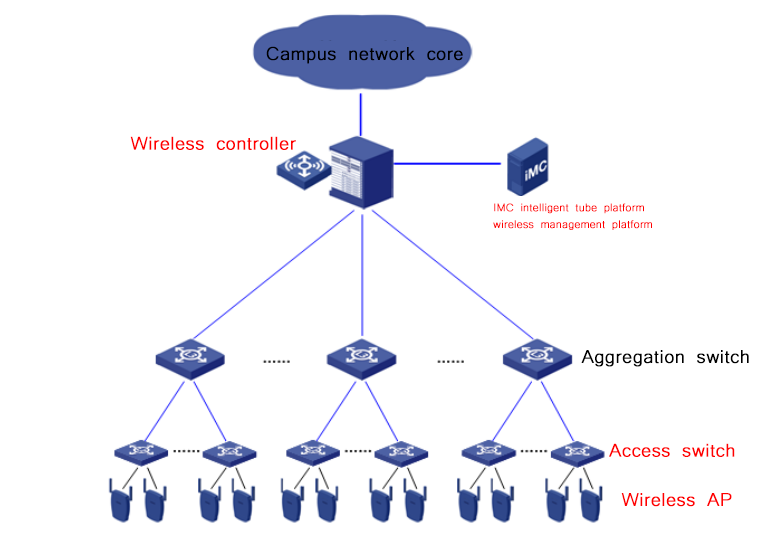

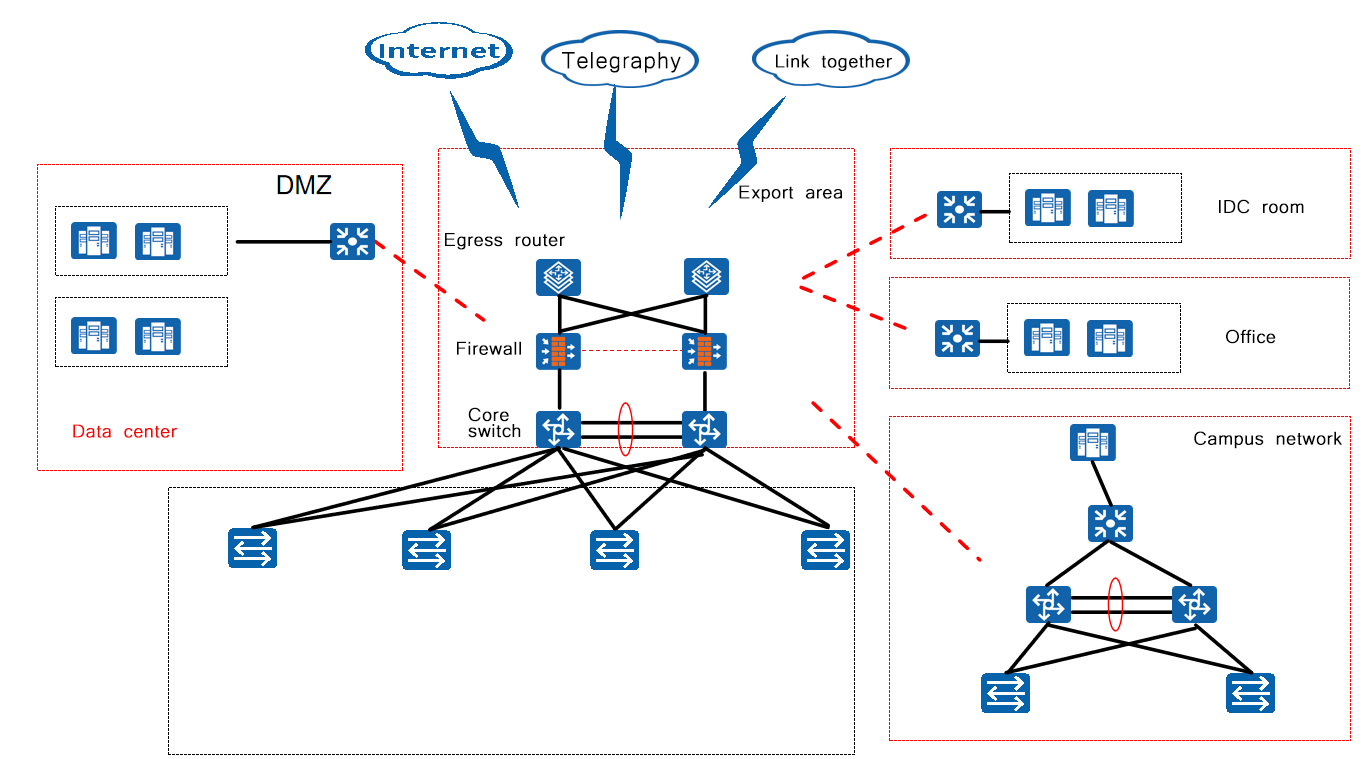

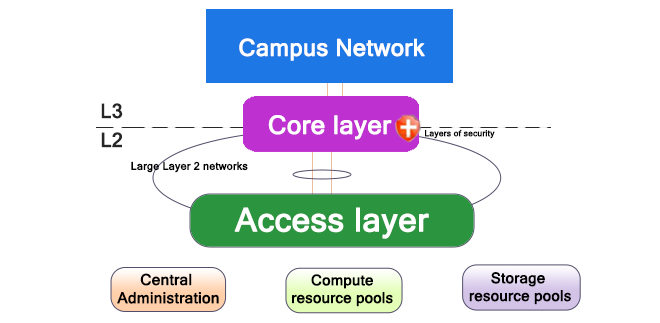

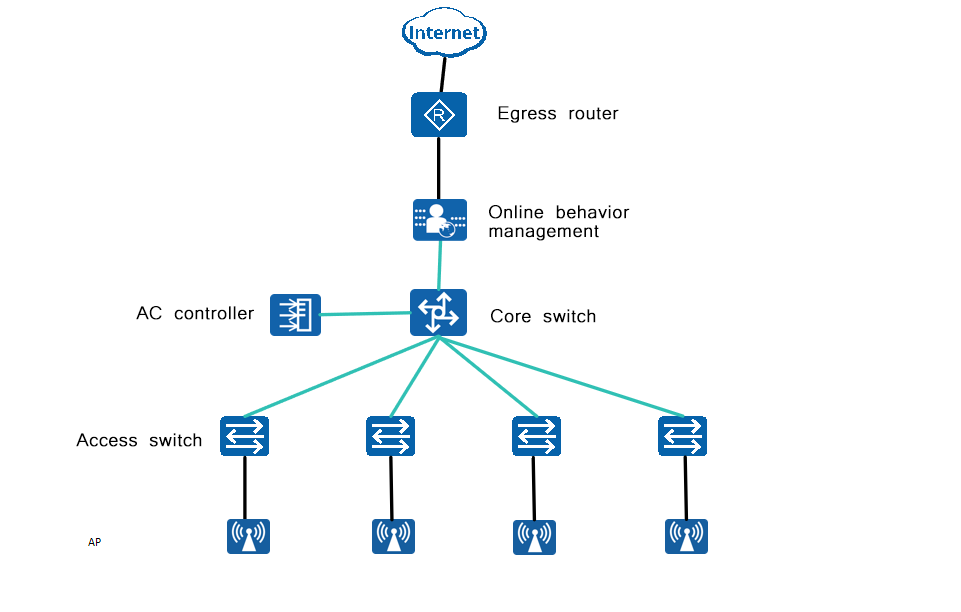

This project mainly involves the wireless network coverage of the unmanned production area and the connection with the office network. The engineers of Netcom Communication use one export firewall for security protection and set up one aggregation switch in both the production area and the office area as a connection point for wireless APs, enhancing the network connection and security of the respective areas.

Product Recommendation

The preferred solution for building an intelligent all-wireless production network LAN for the Suzhou factory is as follows:

- Firewall: USG6325E *1 unit

- Aggregation Switch: S5731-H24P4XC * 2 units

- Wireless AP: AP4050DN *30 units All products are selected from the Huawei brand.

Product Details

| Product Name |

Model |

Product Picture |

Quantity |

Brand |

| Aggregation Switch |

S5731-H24P4XC |

|

2 |

Huawei |

| Firewall |

USG6325E |

|

1 |

Huawei |

| Wireless AP |

AP4050DN |

|

30 |

Huawei |

Project Highlights

The implementation of an intelligent all-wireless production network in the factory not only improves production efficiency and flexibility but also reduces costs and maintenance difficulty. It enhances security and reliability, promotes the development of the Internet of Things and industrial internet, supports remote monitoring and management, and promotes green manufacturing and sustainable development.