This network project is for a newly constructed factory, mainly encompassing office and warehouse areas. The construction involves establishing a main server room on the ground floor, with peripheral devices and floor equipment connected to the server room via fiber optic cables. The project focuses on the procurement of data network equipment for the factory abroad. Through the comprehensive implementation of the new building network construction project, the entire floor's network will be built into a modern, multifunctional, structured, and intelligent integrated network system. The goal of the system construction is to be "technically advanced and applicable, fully functional, safe, and reliable," providing the factory with an advanced information network environment.

Modern production lines in factories often rely on automated equipment and intelligent systems, transmitting large amounts of data in real-time to ensure smooth production. Reliable network setup can help managers transmit information timely, establish high-speed, reliable network connections, and improve production efficiency.

Traditional data transmission methods often rely on manual collection and processing, which are inefficient and prone to errors. Establishing a digital network system can automate data collection, reduce labor input, and improve data accuracy.

A good network system helps managers connect and communicate with department heads through network connections, monitor the production process in real-time, and adjust production plans and resource allocation as needed. This improves the flexibility and accuracy of production scheduling.

Network setup is also crucial for ensuring safety in the factory. Modern factories involve numerous machines and processes, and any faults or accidents can severely impact production and potentially endanger employees' safety. By establishing network monitoring and warning systems, potential safety hazards can be detected and addressed promptly, enhancing the factory's safety and stability.

Network setup in factories is relatively complex and requires a professional technical team or partners to ensure network stability and reliability, including network architecture design, equipment selection, and software integration.

If network equipment comes from different manufacturers, compatibility issues may arise. Professional partners are needed to select suitable equipment to prevent network incompatibility issues.

With the development of the internet, factory networks face increasing security threats, such as hacker attacks, viruses, and data leaks. Companies must implement effective network security measures, such as encrypted communication, to ensure network safety.

After the network setup is completed, professional network management teams or partners are needed for maintenance. If the company lacks dedicated maintenance personnel, it is recommended to choose third-party IT maintenance teams, which can save costs and provide professional maintenance assistance.

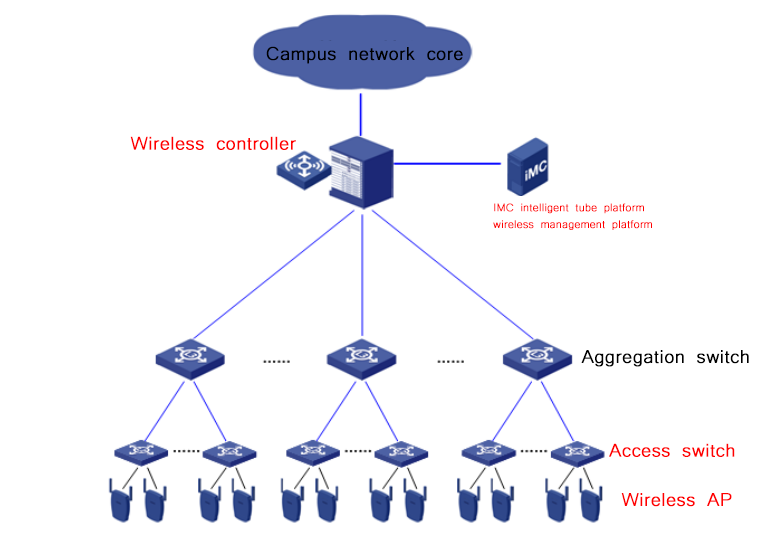

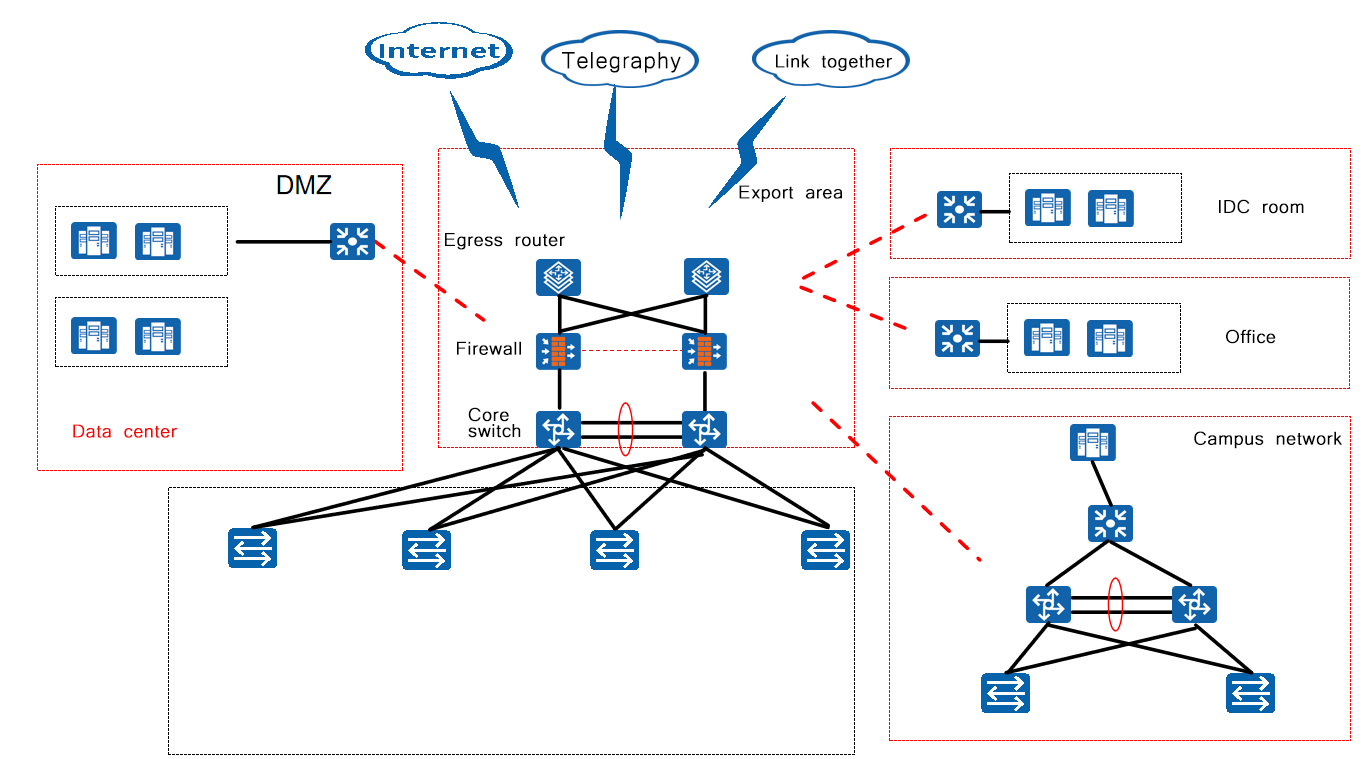

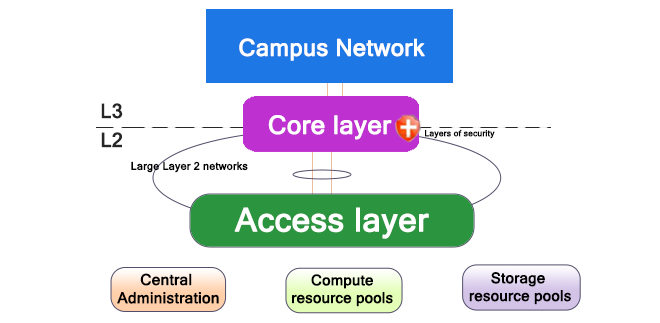

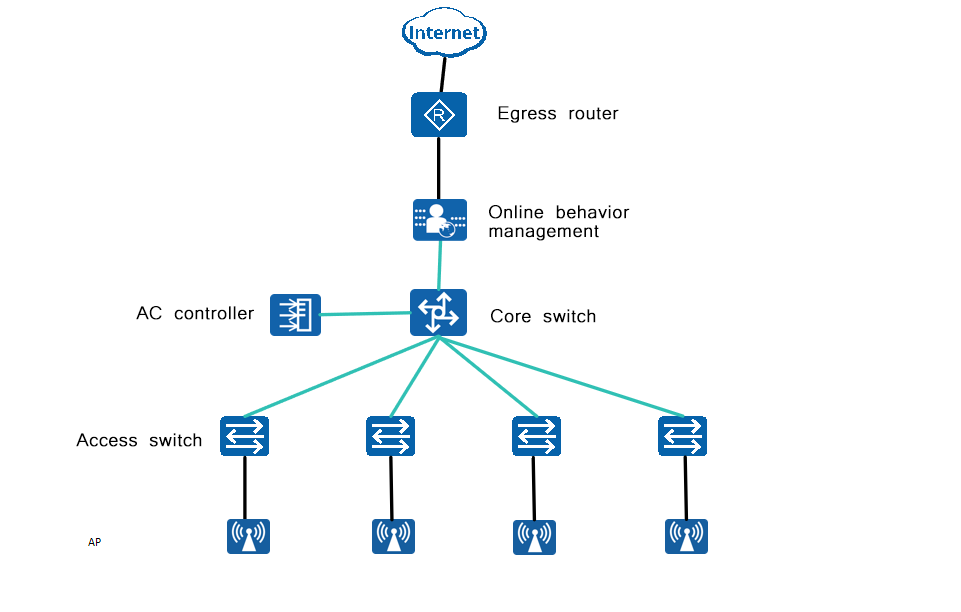

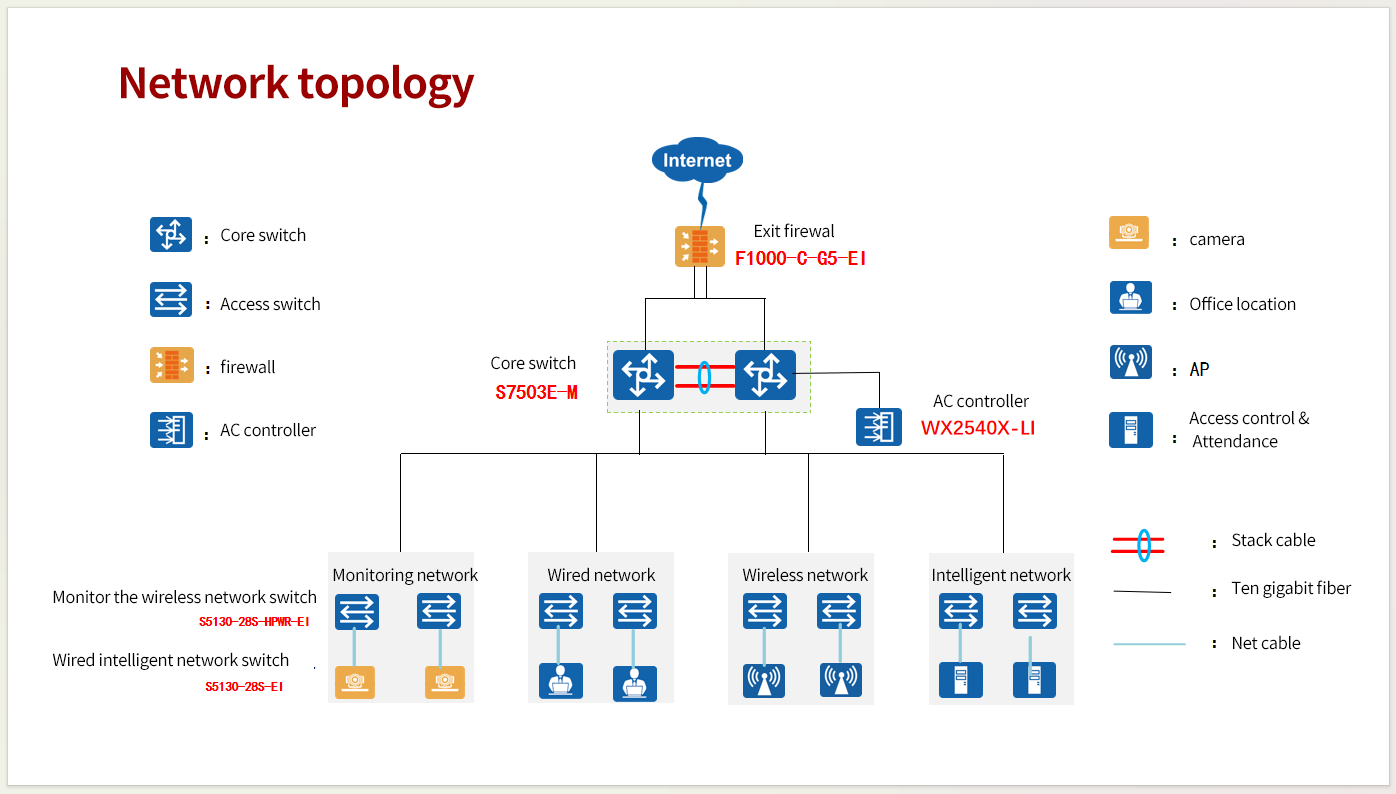

In this factory network project, a three-layer network structure is designed: the access layer, the core layer, and the edge layer. The entire network is primarily positioned as a 10 Gigabit Ethernet backbone network with Gigabit bandwidth to terminals through switches. The network uses a two-layer topology, including the backbone layer (core layer and aggregation layer) and the access layer. The backbone layer aggregates network traffic from the distribution layer, achieving high-performance core switching and transmission. The edge layer uses firewalls as exit devices, connecting to the public network through firewalls.

The preferred solution for setting up the LAN for this factory abroad includes the following H3C products:

| Product Name | Product Model | Product picture | Quantity |

|---|---|---|---|

| Wireless AP | WA6520 |  |

45 |

| Wireless Controller | WX2540X-LI |  |

1 |

| POE Access Switch | S5130S-28S-HPWR-EI |  |

3 |

| Core Switch | H3C S7503E-M |  |

2 |

| Firewall | F1000-C-G5-LI |  |

1 |

Setting up a factory network involves technology, security, compatibility, and cost control. This project considers the factory's area and network needs, creating a network topology based on actual conditions. It ensures high cost-performance construction, reasonable network bandwidth, product selection, and network application. Measures are taken to strengthen security controls, ensuring long-term stable operation of the factory's network system.