Customer Background

In modern industrial production, factories are facing increasingly fierce market competition and ever-changing customer demands. To improve production efficiency, reduce costs, and enhance product quality, factories need to continuously innovate and upgrade their technology. Among these upgrades, the integration of the network system is a crucial part.

A factory in Huizhou has two locations: a new plant area and an old plant area, which are about 7 kilometers apart. The new plant area has four buildings, including two production buildings, one test building, and one dormitory building. The old plant area only has two buildings, namely the production building and the dormitory building. At present, both the new and old plant areas have been comprehensively wired, but they cannot communicate with each other, and the wiring in the old plant area is outdated and cannot meet the current needs of connecting with the new plant area. Therefore, it is necessary to establish a high-bandwidth management platform supported by network technology and modern information technology, which can use information tools such as OA systems, MIS applications, and video conferencing systems to improve office efficiency.

Importance of Network Upgrade

- Improving Production Efficiency: By introducing advanced network technology such as industrial IoT through system integration, the factory can achieve more efficient data transmission and communication between various production equipment within the factory.

- Enhancing Product Quality: Network upgrades help the factory control product quality and consistency. Through comprehensive quality monitoring and data analysis, the factory can monitor various indicators of the products in real-time during the production process to ensure that each product meets quality standards.

- Strengthening Data Analysis and Decision-Making: Network system integration upgrades enable the factory to collect, store, and analyze large amounts of production data better. With this data, the factory can identify production bottlenecks and inefficient reasons, thereby optimizing production processes and configurations to improve the scientific and accuracy of decision-making.

- Improving Safety and Reliability: The upgrade of the system integration network can also significantly improve the safety and reliability of the factory. By introducing advanced network security technologies and protection measures, it can effectively prevent network attacks and data leaks, protecting the factory's core data and intellectual property.

Challenges Faced

With the continuous advancement of Industry 4.0, factories face many challenges in the process of achieving system integration network upgrades. Although the upgrade can bring about improved production efficiency, reduced costs, and enhanced product quality, in practice, factories must overcome difficulties in technology, economy, and management.

- Technical Complexity: The network system integration upgrade involves the application and integration of various advanced technologies, such as artificial intelligence and big data analysis. These technologies themselves are highly complex and require cooperation with professional third-party IT technicians to complete the project construction more accurately and efficiently.

- Reasonable Cost Investment: The network integration project is a high-investment engineering project, involving many aspects such as hardware equipment procurement and software system development and maintenance. Factories must find professional cooperative suppliers to carry out network planning, comprehensive wiring, and equipment purchase to achieve the most reasonable network planning with the optimal solution.

- Data Security and Privacy Protection: The upgrade of the system will inevitably bring a large amount of production data collection and processing to the factory. Once the security and confidentiality of these data are compromised, it will bring significant losses to the factory! To prevent network attacks such as hackers and avoid data leakage issues, factories need to customize a comprehensive security protection system to ensure the safe transmission and storage of data.

Solution

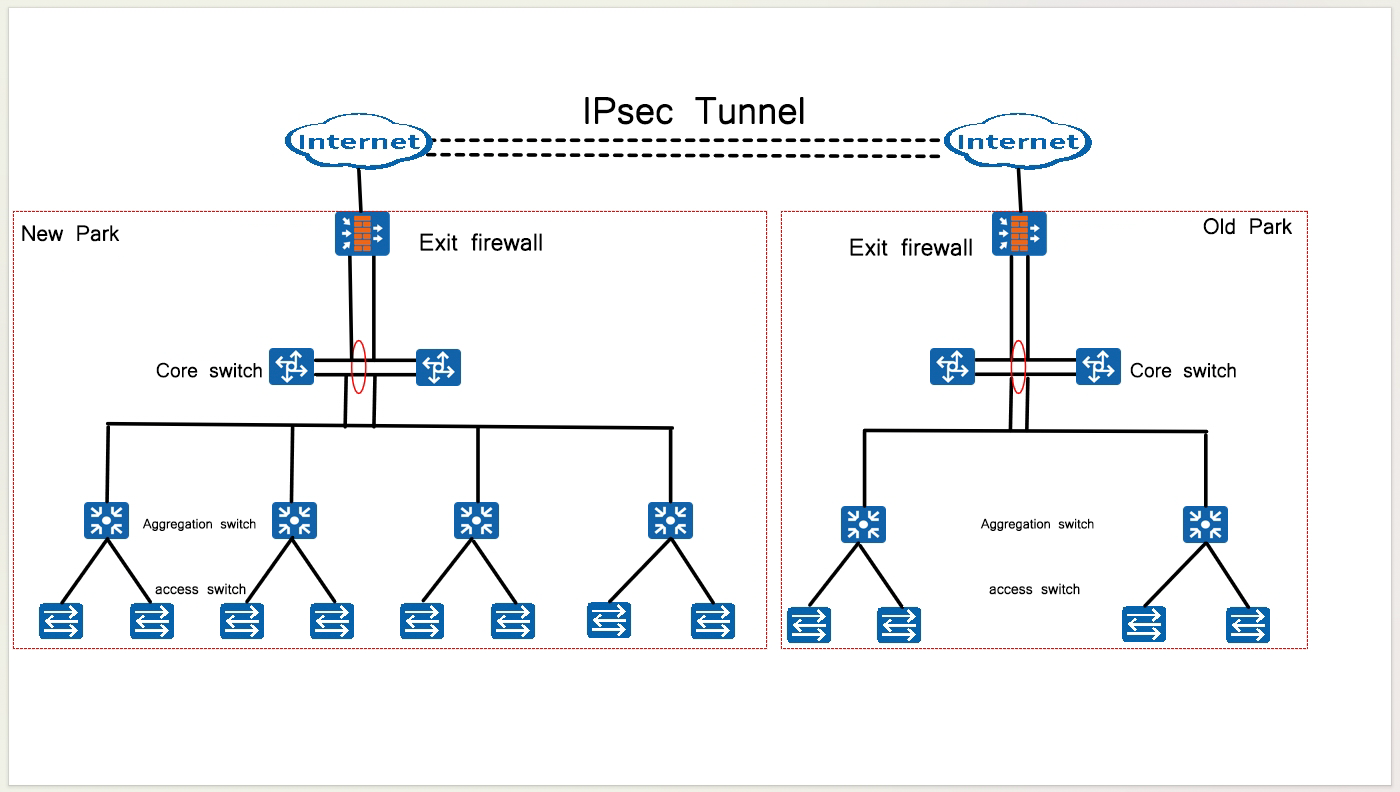

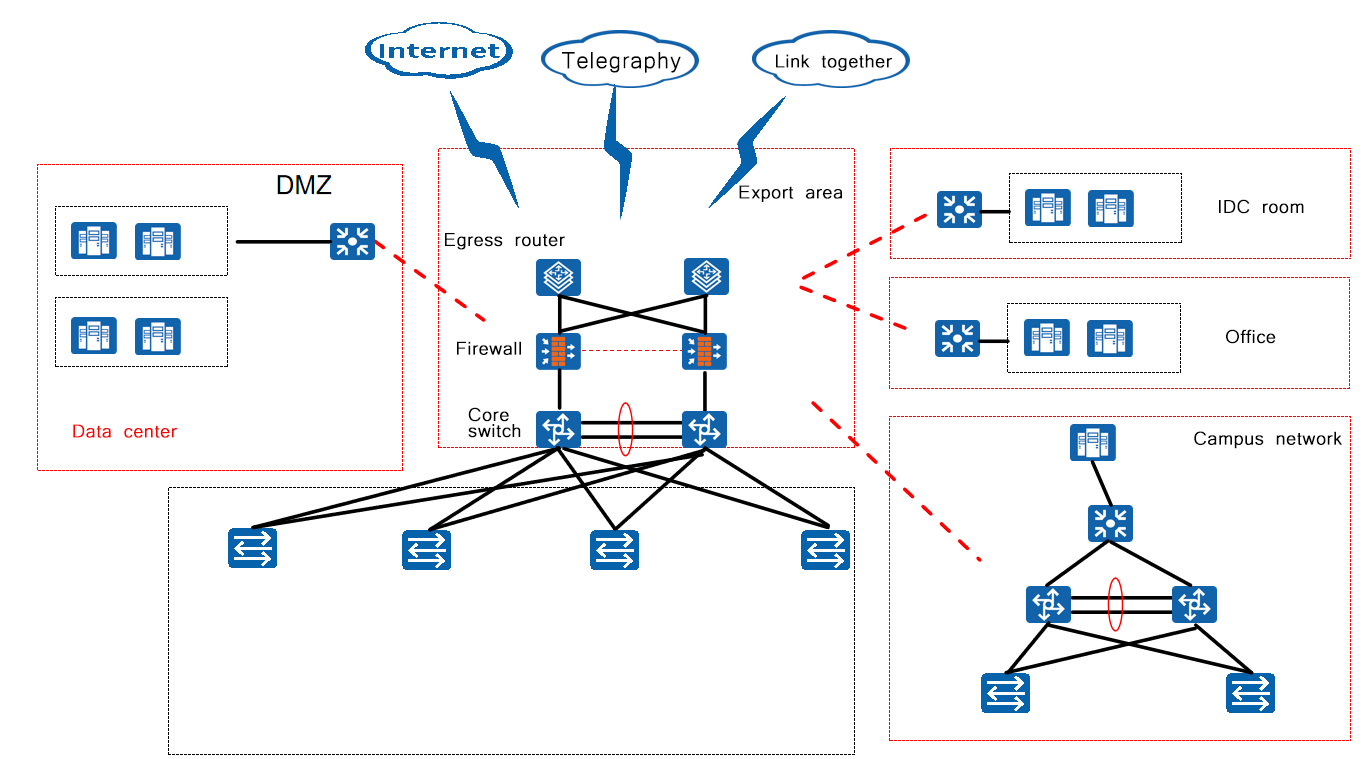

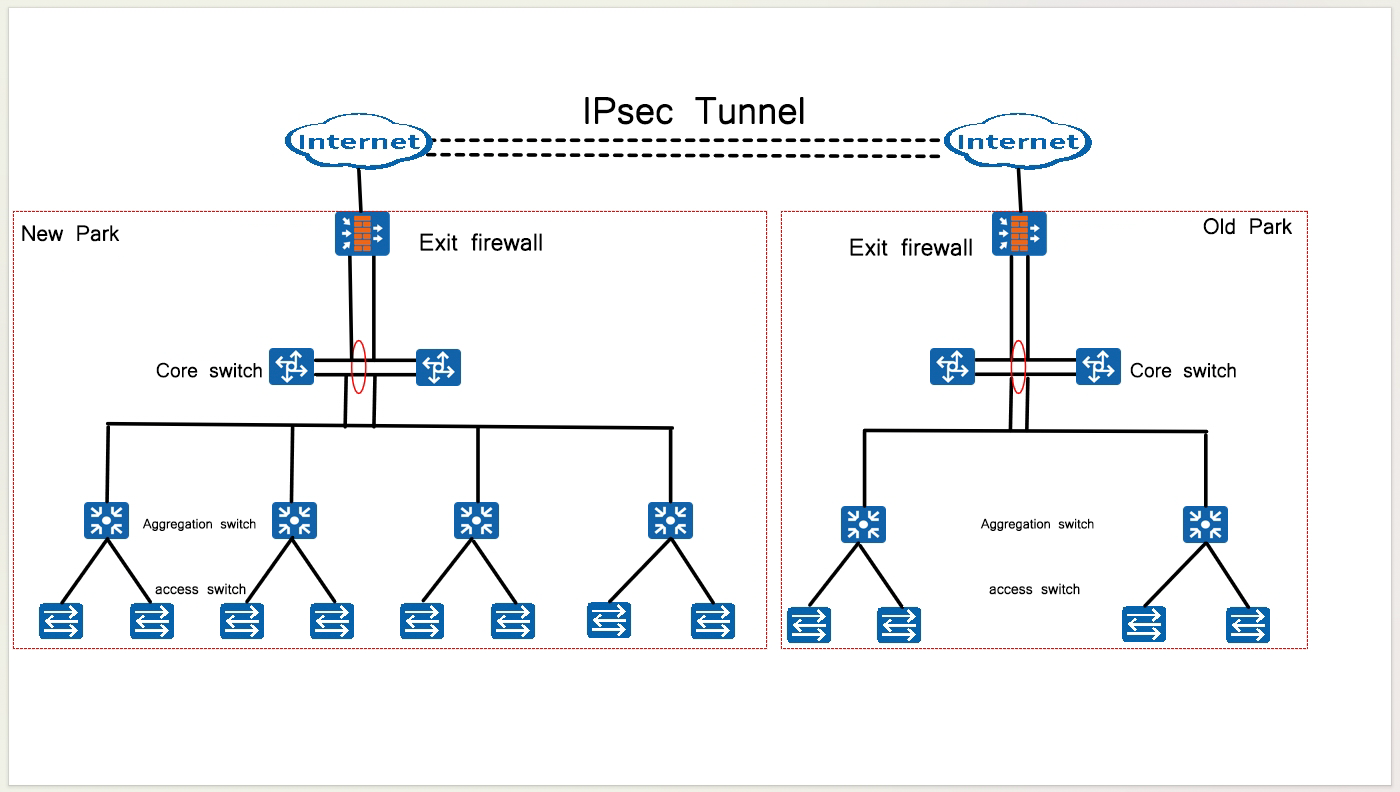

In this Huizhou network upgrade plan, there are two plant areas, new and old, that need to interconnect and visit each other through the network. Due to the long distance between them, the plan establishes an IPsec tunnel through the public network for interconnection and visitation. IPsec VPN protects point-to-point communication, and through IPsec VPN, a secure tunnel connection can be established between network security gateways. The equipment uses H3C high-performance firewalls, whose packet forwarding rate and throughput are leading in the industry, greatly ensuring the network security of both locations.

Product Overview

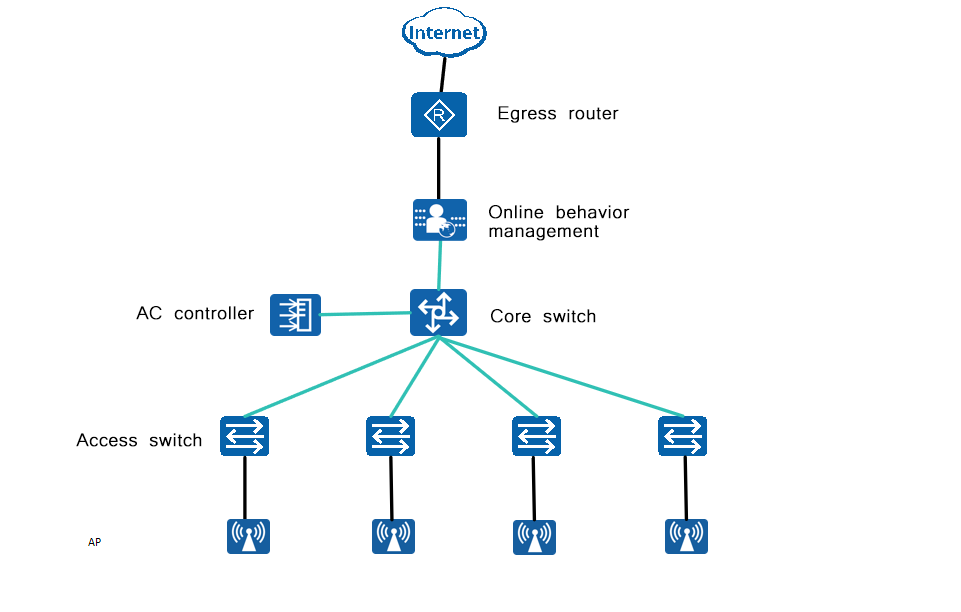

The preferred solution for the network upgrade and local area network construction of a factory in Huizhou is as follows:

- Core Switch: H3C 7503E *4 units

- Aggregation Switch: S6520X-54QC-HI *6 units

- Access Switch: H3C S5560X-EI series * 25 units

- Firewall: F5000-AI-15 * 2 units All the above products are selected from the H3C brand.

| Product Name |

Model |

Product Picture |

Quantity |

Brand |

| Core Switch |

S7503E |

|

4 |

H3C |

| Firewall |

F5000-AI-15 |

|

2 |

H3C |

| Aggregation Switch |

S6520X-54QC-HI |

|

6 |

H3C |

| Access Switch |

S5560X-EI series |

|

25 |

H3C |

Project Highlights

This project has achieved a system integration network upgrade for a factory in Huizhou, which is of great significance in improving production efficiency, enhancing data analysis and decision-making capabilities, improving product quality and consistency, promoting supply chain collaboration, improving safety and reliability, and achieving sustainable development.